RFID technology applied to clothing management

The clothing industry produces several pieces of clothing and pants

every year and transports the clothing to sales locations, such as mass

merchandisers, department stores, and other places. Due to the wide variety of

clothing and the large quantity, management is a big challenge. In the clothing

manufacturing industry, inventory management must be done well and every piece

of clothing must be mastered, so that inventory can be efficient. The clothing

manufacturing industry can also be regarded as a supplier. It must supply the

produced clothes to sellers. The supplier's logistics pipeline must supply

products at the right time and place. In order to ensure the supply of

products, logistics management is also a subject that must be paid attention

to. Therefore, the application of RFID technology in clothing management is a

key.

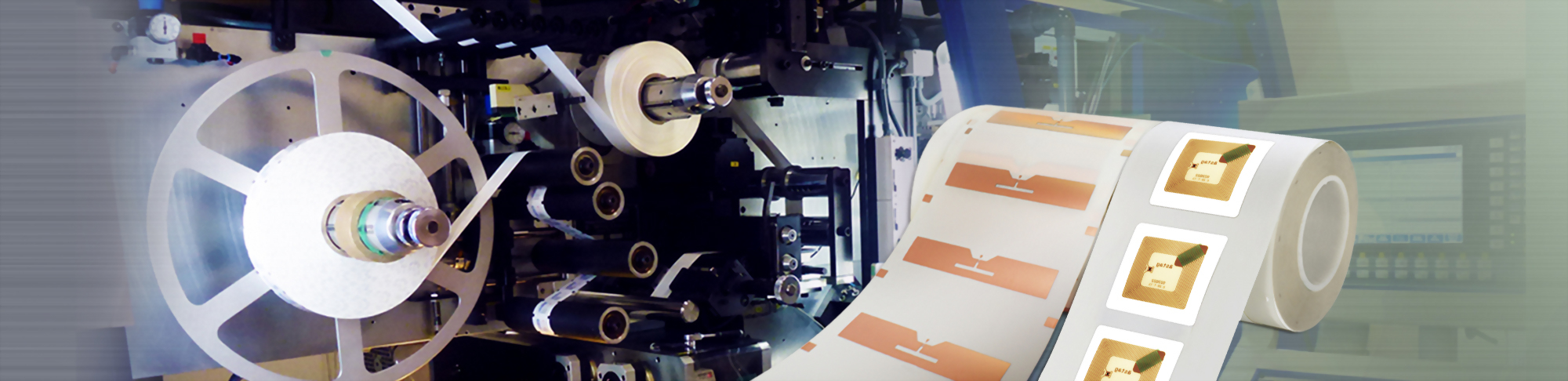

Introducing RFID Labels into clothing management has become a standard equipment in the clothing industry and is also one of the current popular trends. Labels are attached to each piece of clothing, with tracking as the main function. The purpose is to accurately grasp the clothing inside the clothing manufacturing factory. The relevant information such as the name, quantity and storage location of the clothing can also be added to the information of the delivery location. By reading the Labels with a handheld reader, you can not only know the relevant information of the clothes in real time, but also add or modify the information immediately. Through this technical operation, can understand the status of various clothes, not only when taking inventory It will be more efficient and can be classified quickly and accurately. RFID technology can effectively improve management efficiency and convenience, thereby reducing the cost of manpower and time.

Blogs

- RFID technology applied to retailers

- RFID technology applied to vehicle tracking

- RFID technology applied to worker management

- RFID technology applied to clothing management

- RFID technology applied to asset management

- RFID technology applied to business travel management

- RFID technology applied to parts management

- RFID technology applied to consignment management

- RFID technology applied to supply chain management

- RFID Labels are used in storage management

- RFID technology applied to shoes inventory management

- Use RFID technology to analyze product sales

- RFID technology applied to electronic locks

- RFID Wristbands replace cash purchases

- RFID Wristbands used in water parks

- RFID Wristbands used in Marathon races

- Lane access management

- Safety management of electric rolling doors

- Multifunctional Proximity Card

- Elevator Floor Control System

- NFC Labels used in cultural relics management