RFID technology applied to parts management

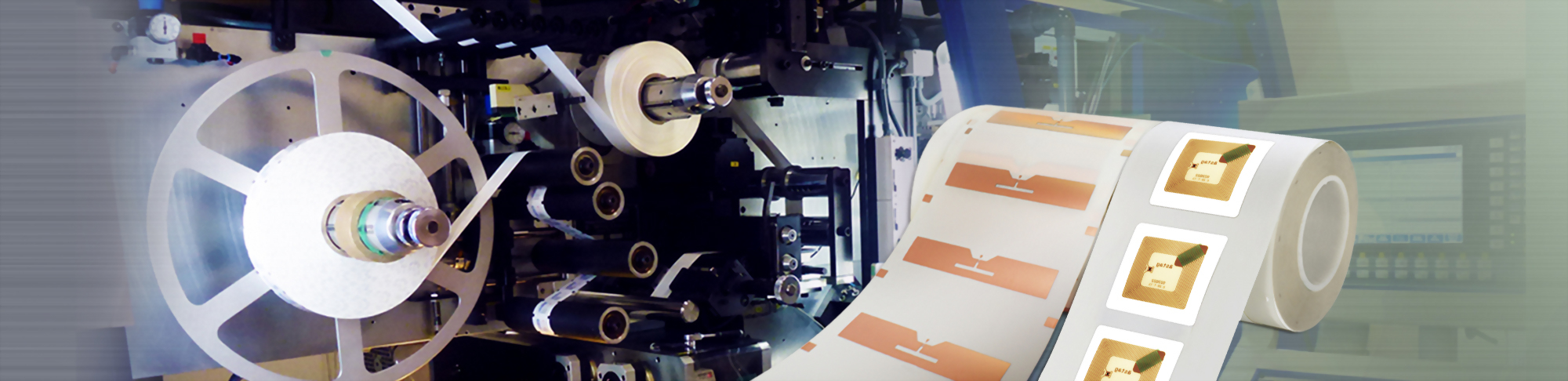

In electronic manufacturing and other related industries, often encounter a large number of parts. Some parts are not only large in quantity but also very small in size. In addition, there are many types of parts, which is a big challenge in management work. Therefore, in order to effectively manage a variety of parts, using a RFID Mini Tag is the best choice. The mini tag is characterized by its small size and light weight. Since this product has a particularly small appearance, it is very suitable for attachment in terms of parts, it can be applied to electronic parts, machine boards, molds, etc. manufactured by electronic and industrial manufacturers. Mini Tag based on RFID technology are used to manage various parts to improve management efficiency.

Since there are many parts or molds inside an electronics manufacturer, it is necessary to classify them accurately and keep track of the location and quantity of the parts at any time. Therefore, the Mini Tag and the back-end management system are combined to achieve efficient management. Install the Mini Tag on each part, and then use the reader to read it. While reading, the relevant information of the part will be automatically stored in the system, such as the name, quantity, storage location and other information of the part. When taking inventory, can query it from the management system. With the Mini Tag, don’t have to check them one by one. Can use the reader to read the Mini Tag on the parts. Can accurately grasp the parts quantity without direct contact. RFID technology can effectively help classification to prevent parts or molds from being used incorrectly, so Mini Tag are very suitable for parts management applications. It can not only improve management efficiency, but also effectively reduce labor and time costs.

Blogs

- RFID technology applied to retailers

- RFID technology applied to vehicle tracking

- RFID technology applied to worker management

- RFID technology applied to clothing management

- RFID technology applied to asset management

- RFID technology applied to business travel management

- RFID technology applied to parts management

- RFID technology applied to consignment management

- RFID technology applied to supply chain management

- RFID Labels are used in storage management

- RFID technology applied to shoes inventory management

- Use RFID technology to analyze product sales

- RFID technology applied to electronic locks

- RFID Wristbands replace cash purchases

- RFID Wristbands used in water parks

- RFID Wristbands used in Marathon races

- Lane access management

- Safety management of electric rolling doors

- Multifunctional Proximity Card

- Elevator Floor Control System

- NFC Labels used in cultural relics management