RFID technology applied to shoes inventory management

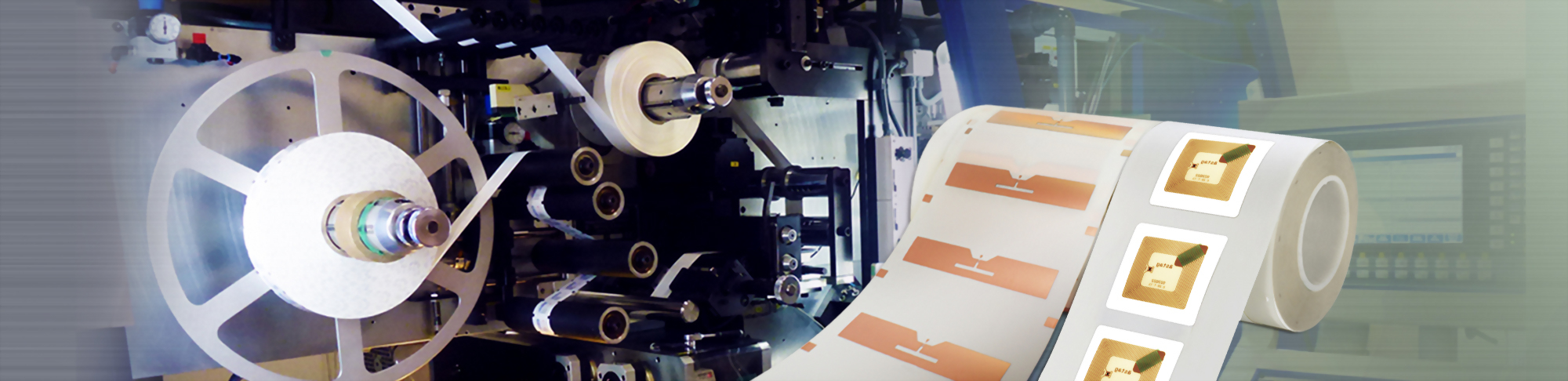

Because there are many kinds of shoes, with different brands,

colors, and sizes, in order to improve management efficiency, using RFID Labels

is the best choice. First, stick the RFID Label on the shoe box, or embed the

Label without affecting the appearance of the shoes. The relevant information

of each pair of shoes will be written on the Label, and the Label will be read

with a handheld reader. The read information will be stored in the management

system. On the supplier side, the shoes produced are all equipped with RFID

Labels, and are inventoried through the management system, and then accurately

classified. The system can also add a new item of product delivery location

information.

On the seller's side, when the shoes are purchased, a handheld reader is used to read the Labels, and the relevant information of the product will be stored in the system. When the merchant performs inventory or inquiry, the sales staff can quickly find the shoes and serve the customers. At the same time, can also make inquiries through the system to deliver shoes that meet customer needs as quickly as possible. On the other hand, sellers can use the management system to see which shoes are insufficient and need to be replenished, and then can notify suppliers to assist in replenishment and keep an eye on the inventory status to prevent shortages. Therefore, applying RFID technology to shoes inventory management can easily grasp the trends and quantities of various shoe styles, thereby effectively improving management efficiency and reducing labor and time costs.

Blogs

- RFID technology applied to retailers

- RFID technology applied to vehicle tracking

- RFID technology applied to worker management

- RFID technology applied to clothing management

- RFID technology applied to asset management

- RFID technology applied to business travel management

- RFID technology applied to parts management

- RFID technology applied to consignment management

- RFID technology applied to supply chain management

- RFID Labels are used in storage management

- RFID technology applied to shoes inventory management

- Use RFID technology to analyze product sales

- RFID technology applied to electronic locks

- RFID Wristbands replace cash purchases

- RFID Wristbands used in water parks

- RFID Wristbands used in Marathon races

- Lane access management

- Safety management of electric rolling doors

- Multifunctional Proximity Card

- Elevator Floor Control System

- NFC Labels used in cultural relics management