A Brief Talk on RFID Building the Key Foundation of Smart Manufacturing

Smart manufacturing attaches great importance to the transparency and real-time concatenation of production information, and the sensors used as the basis for data collection are indispensable in the construction of infrastructure. And every object in the factory can have radio frequency identification (RFID) technology such as "identity card". With the current price down, it is also expected to explode in multi-scenario applications, such as smart manufacturing.The current hot production history Application, RFID can play a very important role in it.

What is RFID?

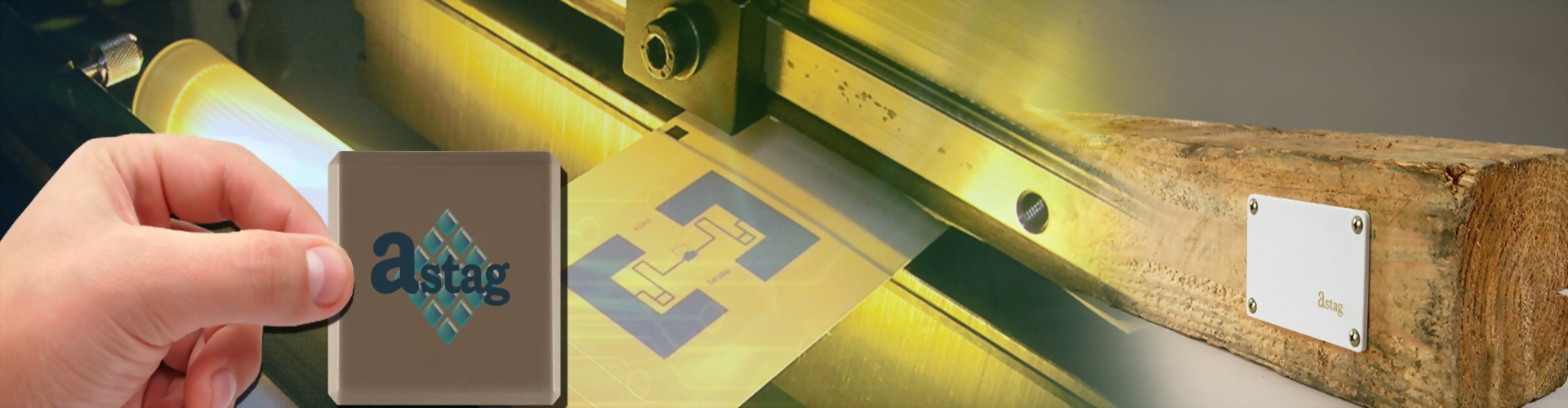

RFID is mainly composed of an electronic tag (Tag), a reader (Reader) and a computer system. The digital data in the chip in the electronic tag is transmitted to the reader in a non-contact manner through wireless communication technology. The reader Then, the captured and recognized information is sent to the back-end computer application system for further processing, use or value-added use of the data.

In addition to the ability to sense responses through reading, RFID also adds a write function, so in addition to transmitting information to the outside world, by writing information, it becomes a storage space for related information, and also makes objects seem like more "identity cards" In terms of product production history application, it can record the product price, assembly date, shipping factory, current location, etc.

Compared with traditional barcodes, the characteristics of RFID have many advantages, including fast scanning speed, simultaneous processing of multiple data, and data storage function, and the data can be updated and modified, reusable, oil and stain resistant. According to the analysis of the Economic Research Center of the Industrial Research Institute, if the processing efficiency of manual, barcode and RFID for one data identification is compared, the results show that the manual is about 10 seconds, the barcode scan is 2 seconds, and the identification through RFID takes only 0.1 seconds.

RFID builds the foundation of smart manufacturing

RFID has a wide range of applications. Since the popularization of RFID, it was initially mainly used in logistics. However, it has been widely used in retail, logistics, transportation, medical treatment, and manufacturing. Although RFID is not a new technology, with the advent of the smart era, the industry has continued to develop various RFID application scenarios through market demand in recent years. In terms of smart manufacturing, in view of the demand for resources and cost efficiency, various manufacturers have begun to use RFID technology to achieve real-time location tracking, asset or personnel monitoring, production line process control and supply chain management applications.

For example, in the past, the production site of the manufacturing industry had a large proportion of manual interventions, often requiring manual recording of large amounts of data, resulting in low accuracy and efficiency. Therefore, manufacturers are now beginning to use the features of RFID-writable information, as long as RFID readers are installed at the entrances and exits of production lines or production machines, when RFID-labeled work orders or raw material carriers pass by, they read The device will automatically read and record all the information of the product from entering the workstation to leaving, as well as the specific processing information of the original materials. In addition to eliminating the previous manual one-by-one scanning process, greatly reducing labor costs or operating time, it can also ensure that During mixed production, identify the correct processing program.

Outside the factory, the establishment of information sharing mechanisms upstream and downstream of the supply chain has become the future development trend of smart manufacturing. Now suppliers can also use this to obtain product logistics and market sales information, and draw up factory production plans accordingly to reduce the inventory of goods and control costs.

And every product from upstream supplier to downstream retailer can track the flow of goods through information sharing to reduce the cost loss caused by the wrong delivery, theft and damage of goods.

RFID is a technology that makes message processing more rapid and simplified, but how to apply the message more effectively in the future is where the value lies. The large amount of RFID data generated by the close interconnection of various devices needs to be effectively managed and analyzed, which also encourages RFID manufacturers to continue to innovate to seize this wave of opportunities, such as the development of tags with higher memory capacity and software with a BI layer Platform, and cloud-based solutions, or further fully integrated with IT systems, such as ERP, MES, PLM, etc.

Original URL : https://www.digitimes.com.tw/iot/article.asp?cat=158&id=0000584785_1Z5805EP75GK8P6MQ4AHO&ct=v